LAPOXY Ground Anti-slip Treatment Agent

Lapoxy Anti-skid Treatment Solution is used to etch all high gross ceramic floor tiles, glass floor, natural stone and concrete surfaces. When following the instruction to apply, Lapoxy AST is able to react with the slippery surfaces, providing a 「suction like」non-skid property. It is very suitable for all slippery tile surfaces in corridors, stair steps, ramp, pathway of swimming pools, restaurants in interior or exterior areas. The products is suitable for elder centres, kindergartens, medical centres, canteens, food processing factories. This is an environmental friendly, non-toxic, developed by LAPO Material Innovation (GZ) Ltd.

PROPERTIES

✔ Non-film forming, do not influence the colour and pattern of the tiles or stone.

✔ Anti-skid by "suction" effect, more effective on wet surface. Double the coefficient of friction.

✔ Surface treatment, quick application, reduce down time.

✔ Physical non-skid property, long lasting.

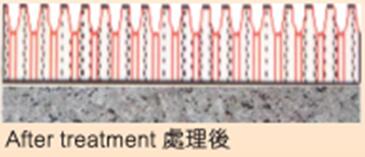

MECHANISM

Ceramic or glaze tiles are highly dense surfaces and there are small and narrow capillary.Coefficient of friction on wet surface is 0.2-0.4

After treated with Lapoxy AST, the capillaries will become bigger and some close end pits will be formed on the surface. All these act as numerous 「suction」providing a non-skid effects on the shoes or bare feet. Coefficient of friction on wet surfaces increase to 0.8-0.9.

USAGES

All those areas slippery tiles installed but need to be converted to non-skid floor for safety purpose.

A . Home

Toilets, Kitchen, Elderly Room, Balcony.

B . Medical Institute

Hospital, Clinic, Elderly Center

C . Education Institute

Nursey, School

D . Public areas

Toilets, Swimming Pool, Bathroom, Markets, Canteen.

E . Industrial

Food processing plants, Medicine factory, Beverage Factory.

Suitable substrates

Glass tiles

Glass tiles

Natural Stones

Natural Stones

Ceramic floor tiles

Ceramic floor tiles

Concrete surface

Concrete surface

Application method

1.

Clean the floor thoroughly with detergent solution and allow to dry completely.

2.

Apply Lapoxy AST on the floor surface by low pressure spray gun and maintain the wet film thickness for 20 minutes.

3.

Rinse the surfaces with plenty of fresh water.